MILLING & SCREW MACHINING

Ceramic / High Performance Plastics

Ceramic and performance plastic components are widely used in the manufacturing industry due to their complementary properties that enhance product performance and durability.

Ceramics are advanced materials known for their exceptional thermal stability, hardness, wear resistance, and corrosion resistance. Industrial ceramics such as alumina, zirconia, silicon carbide, and steatite are commonly used in applications requiring high mechanical strength, electrical insulation, and resistance to harsh environments. They are essential in sectors like automotive, aerospace, electronics, and energy production for components such as bearings, sensors, refractories, and semiconductor parts. Ceramics can withstand high temperatures and aggressive chemical conditions, making them ideal for demanding manufacturing processes.

Performance plastics, particularly fiber-reinforced plastics, offer versatility, cost-effectiveness, and noise reduction. These plastics are often composites combining polymers with fibers like glass, carbon, or aramid (e.g., Kevlar), which improve strength, flexibility, and heat resistance. They are used extensively in industries such as automotive, aerospace, marine, and construction. Plastics can also serve as binders in ceramic manufacturing, aiding in shaping and sintering processes before being burnt off

Moreover, ceramic-filled plastics combine the best of both worlds by integrating ceramic particles into plastic matrices (e.g., PEEK combined with technical ceramics). This hybrid material exhibits enhanced hardness, stiffness, dimensional stability, and barrier properties against gases and liquids, making it highly suitable for precision applications in the semiconductor industry and other high-tolerance manufacturing fields.

In summary, ceramics provide high strength, heat resistance, and durability for harsh environments, while performance plastics contribute flexibility, light weight, and cost efficiency. Together, they enable manufacturers to optimize product performance across a wide range of industrial applications

Electronic Discharge Machine (EDM) / Grinding

EDM is a nonconventional machining process that removes electrical conductive materials according to the thermal energy (melting and partial vaporization of the workpiece) produced by series of sparks occurring between the electrode and workpiece.

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. There are a number of grinding processes – they all help to remove material burrs from the machining process, as well as help to meet tight tolerances.

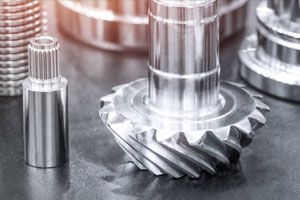

Gears: Spur, Helical, Spline, Worms, Bevel & Keyway

The manufacturing of precision gears involves several specialized cutting processes, including hobbing, shaping, broaching, and milling, each selected based on the gear type and required accuracy. The process typically starts with preparing a gear blank from materials like steel or aluminum, followed by cutting the gear teeth using CNC machines for high precision and repeatability. After cutting, finishing operations such as grinding or honing are performed to achieve the desired surface quality and tight tolerances essential for smooth gear operation. Finally, rigorous inspection and quality control ensure that the finished gears meet strict dimensional and performance standards required for critical applications.

Screw Machined

Multi-Spindle Davenports, single spindle Brown & Sharpes, 6 – 8 spindle Wickmans and Kira machining centers are all machines that turn rod stock into screw machine parts, with typical diameters ranging from .060” to 2.75”. The Swiss Tornos and Escomatic machines are suited for rod stock with diameters ranging from .015” to 1.25”.

Specific Machine Capabilities:

- Wickman machines are 6 – 8 spindle machines specializing in high volume, precision screw machine components;

- Brown & Sharpe machines are single spindle, capable of efficiently producing parts in smaller quantities.

- Davenport machines are best for smaller diameters, multi-faceted parts but large quantities. Having the capability to have 5 spindles means, 5 secondary processes may be performed automatically: turning, drilling, tapping, reaming, broaching, boring, threading, slotting, milling, etc.

- Swiss Tornos machines are best utilized for a lengthy screw machine part with a small diameter. A guide bushing supports the work piece and sliding headstock ensures tighter tolerances and consistent finishes.

- Escomatic machines are coil-fed machines, where the cutting tools revolve around the material, offering a significant advantage in minimizing load time and maximizing output. Escomatics are best for very tight concentricity for a lengthy part, high volume needs, with excellent repeatability.

Centerless Grinding

Centerless grinding is a finishing technique used to have the exact amount of material removed to make a perfectly finished work piece. There are a number of grinding processes – they all help to remove material burrs from the work piece, as well as help meet tighter tolerances.

CNC Milled / Turned

CNC Milling

CNC Turned

CNC milling uses a rotating tool, while CNC turning uses a rotating part for cutting excess material away from the work piece. While milling machines create complex parts from blocks of metal by carving away the excess material, turning is commonly used for cylindrical parts like shafts.

CNC Milled and Turned components generally require secondary operations such as broaching, slotting, bending, crimping, thread rolling, drilling or tapping.

Prototyped Machined Parts:

Prototype or pre-production machined parts can be made utilizing the EDM, lathe, waterjet, laser or milling processes.